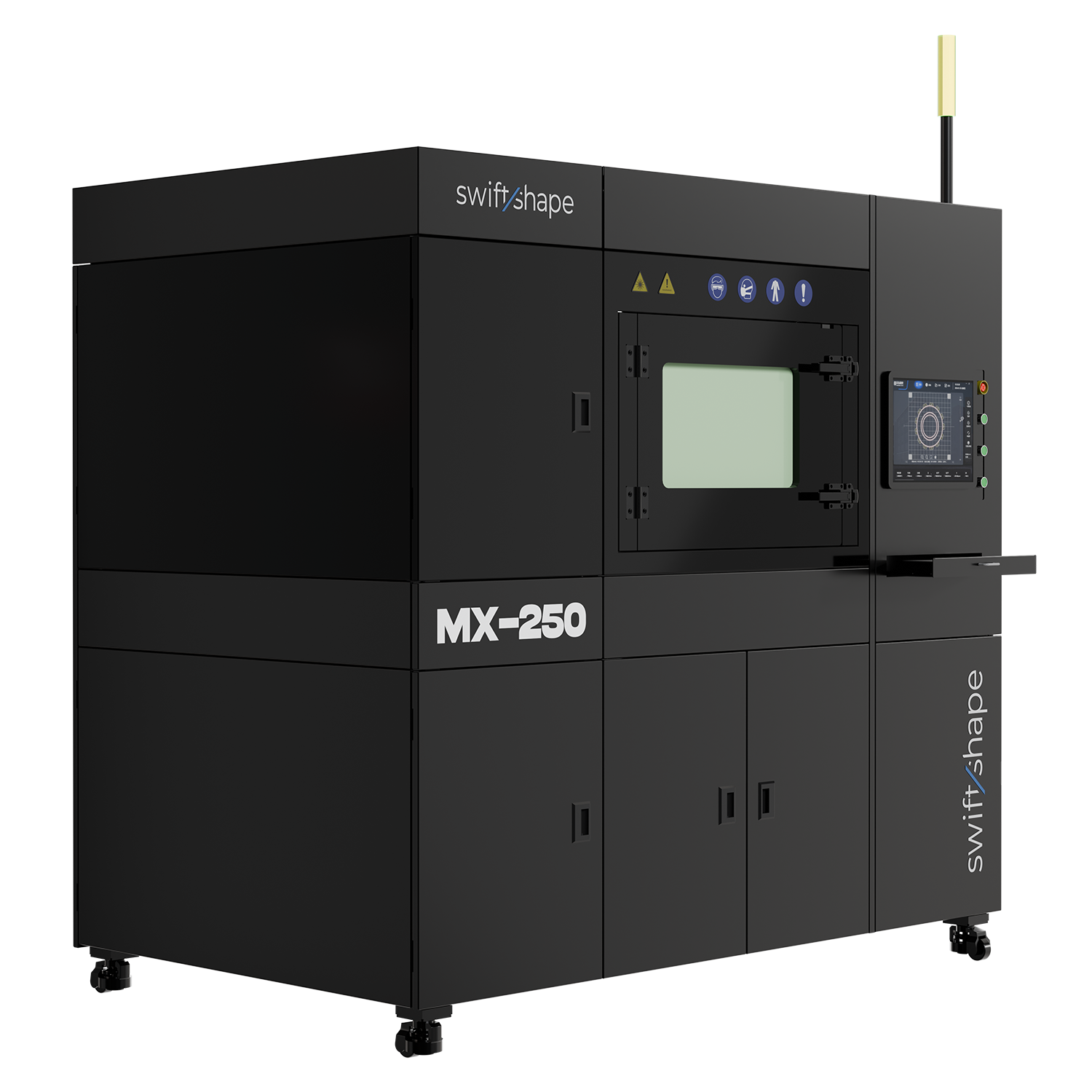

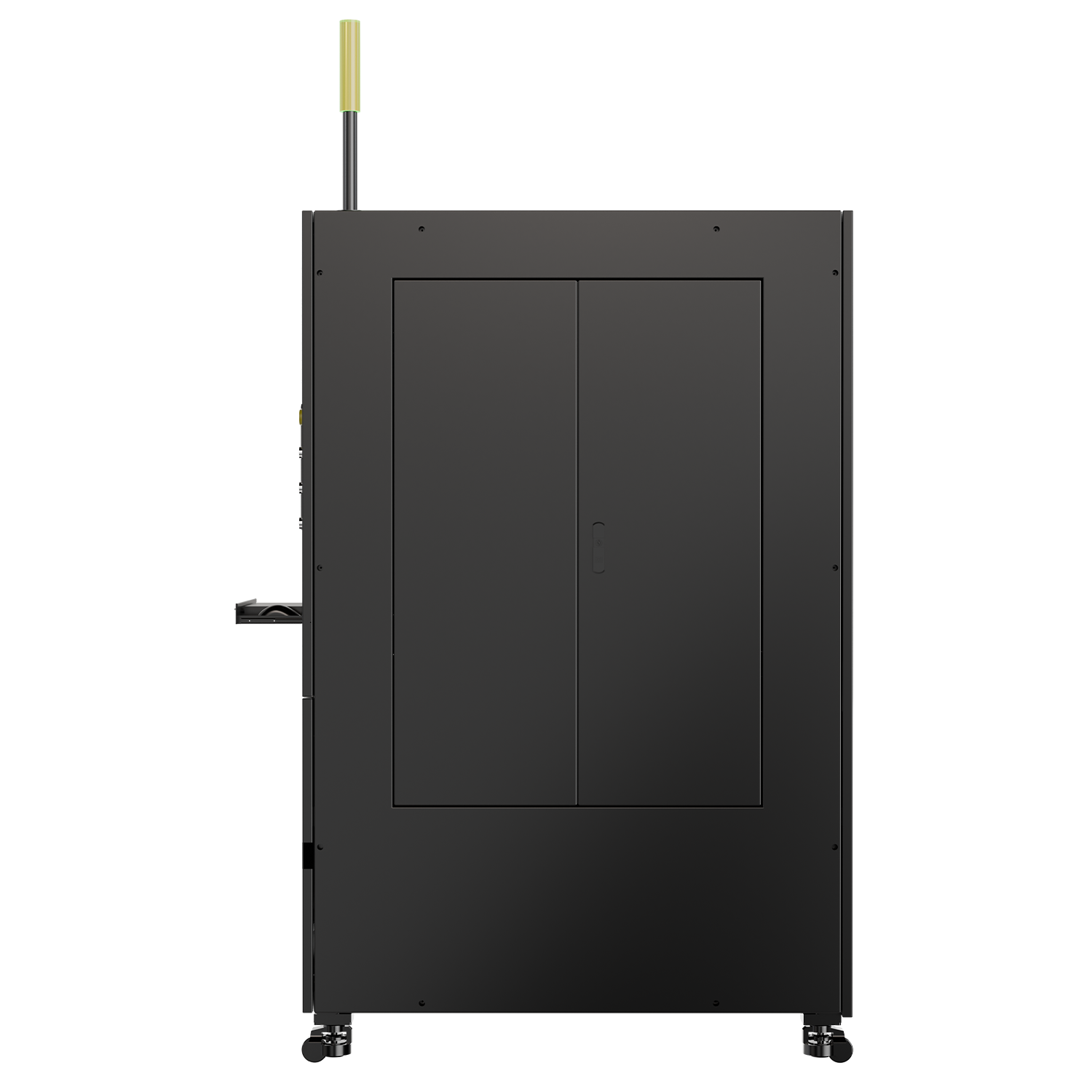

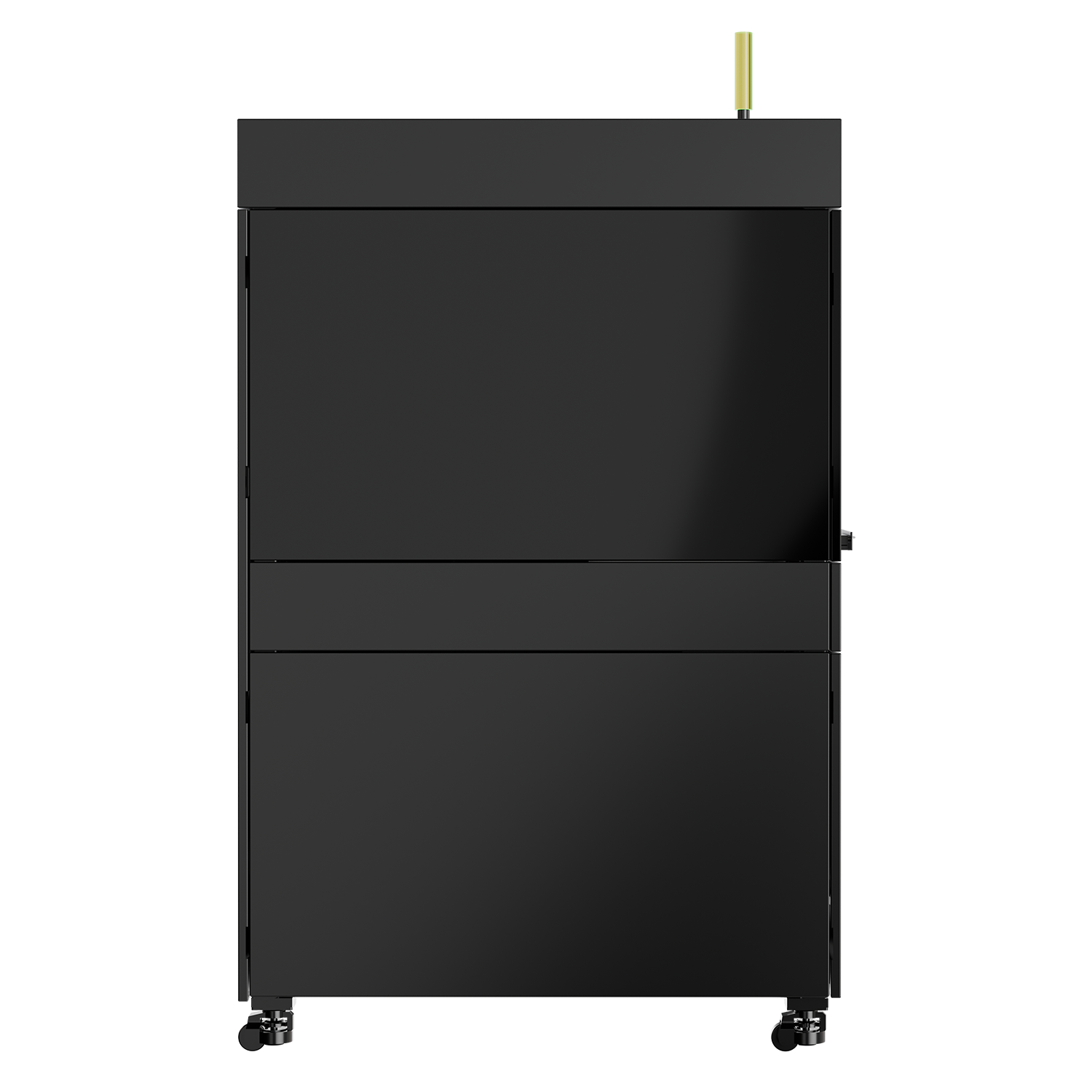

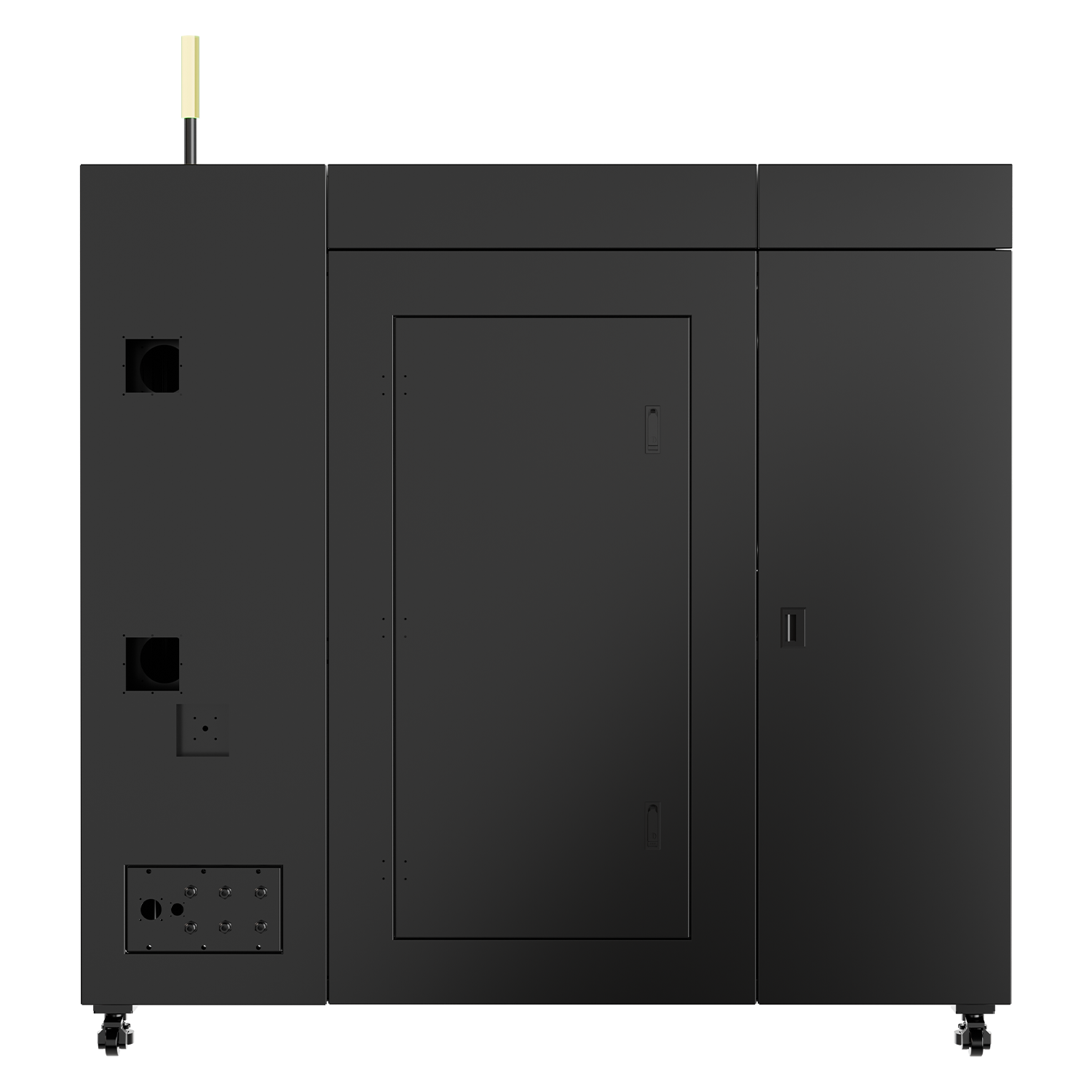

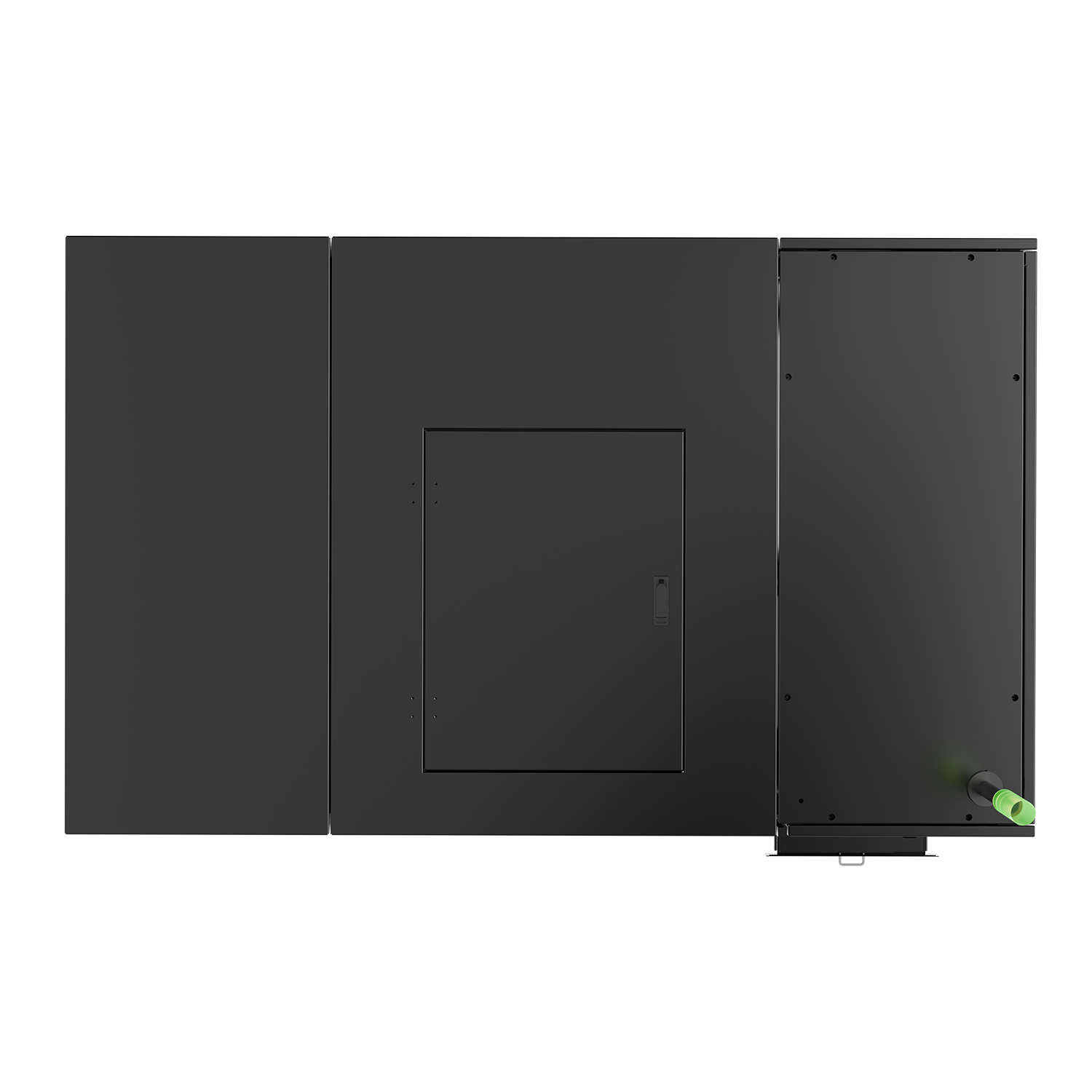

Configure your MX-250

Take Your Business to the Next Level

Discover the difference with the MX250 Industrial Fiber Laser Cutting Machine. Precision, power, and efficiency have never been more accessible. Contact us today for more information.

Features

Dual-Laser Power. Precision at Speed.

The MX250 is built for serious throughput, without sacrificing precision. With a large build volume and two fully independent lasers that cover the entire print area, it significantly reduces build times while maintaining the exceptional accuracy and surface quality demanded in critical applications.

Advanced Multi-Laser Scanning Strategy

Our precision-tuned scanning algorithms and calibration systems ensure seamless coordination between lasers, minimizing overlap artifacts and delivering uniform, high-quality results across the entire build.

Superior Surface Finish

Minimal post-processing, smoother parts, right out of the printer. Ideal for functional components, prototypes, and medical or aerospace-grade applications.

Unmatched Accuracy

Achieve fine details and tight tolerances with exceptional repeatability. The MX series sets a new benchmark for print fidelity in the metal 3D printing category.

Versatile Material Compatibility

Titanium, stainless steel, aluminum, cobalt-chromium, copper and more. The MX250 gives you real versatility, whether you’re iterating designs or manufacturing end-use parts.

Effortless Operation

User-friendly software and intuitive controls make setup and operation simple, even for those new to metal 3D printing. Spend less time on training and more time producing functional metal parts.

Low Operating Costs

Efficient powder usage, low maintenance requirements, and no hidden overhead. The MX100 is built to keep your cost per part down, and your ROI up.

Technical Specifications

Build volume

Laser power

Layer height

Print technology

Supported materials

Max speed

Max build rate

Laser beam diameter

Dimensions

Weight

Voltage

Exceptional Service

When you choose the MX250, you gain more than a machine. You gain a partner in success. Our comprehensive service package includes:

- Free On-Site Installation and Training Our professional technicians and engineers ensure you’re up and running quickly and efficiently.

- 2-Year Warranty Enjoy peace of mind with our extensive warranty coverage.

- Lifetime Support Access our US-based technical support team anytime for expert assistance.

Get your custom quote

Thank You!

We are reviewing your custom quote and will contact you by telephone or email in 24 Hours.

For immediate service, email us at sales@swiftshape.com