SwiftShape LX30:

The Ultimate Creative Machine

Laser Cutter & Engraver, 3D Printer, & CNC Router

Choose Between Two Powerful LX30 Models—Cut, Engrave, and 3D Print with One Cutting-Edge Desktop Machine.

What Sets the LX30 Apart

3-in-1 Functionality

One Design, Endless Possibilities

Unlock the power of innovation with a multifunctional desktop device that combines a CO2 laser machine with CNC routing and 3D printing—three advanced technologies in one groundbreaking tool.

The LX30 revolutionizes workspace efficiency and eliminates the need for multiple machines, allowing for a seamless transition between functions.

Experience the groundbreaking innovation of combining laser cutting, CNC routing, and 3D printing in one powerful, multifunctional device. The LX30 revolutionizes workspace efficiency by integrating these three advanced technologies, eliminating the need for multiple machines and allowing for seamless transition between functions.

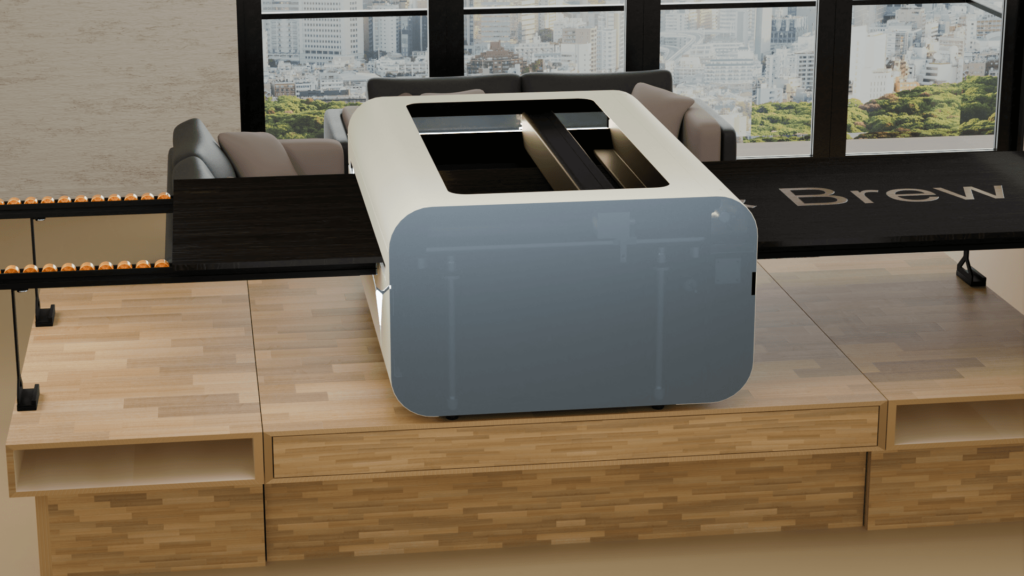

The LX30 offers an impressive working area of 30″ x 16″ in a compact design that fits easily on most desktops, delivering an exceptional size-to-working-area ratio with virtually no wasted space. This innovative layout maximizes productivity by allowing you to handle large projects without needing a large machine, making it perfect for small workshops or home studios while still providing the functionality of a full-scale manufacturing tool.

Working Area + Compact Size

Big Projects in a Compact Space

The LX30 offers an impressive working area of 30″ x 16″ in a compact design that fits easily on most desktops, delivering an exceptional size-to-working-area ratio with virtually no wasted space.

This innovative layout maximizes productivity by allowing you to handle large projects without needing a large machine, making it perfect for small workshops or home studios while still providing the functionality of a full-scale fabrication machine.

Power Capability + Max Cutting Depth

Unmatched Power for Deep Cuts

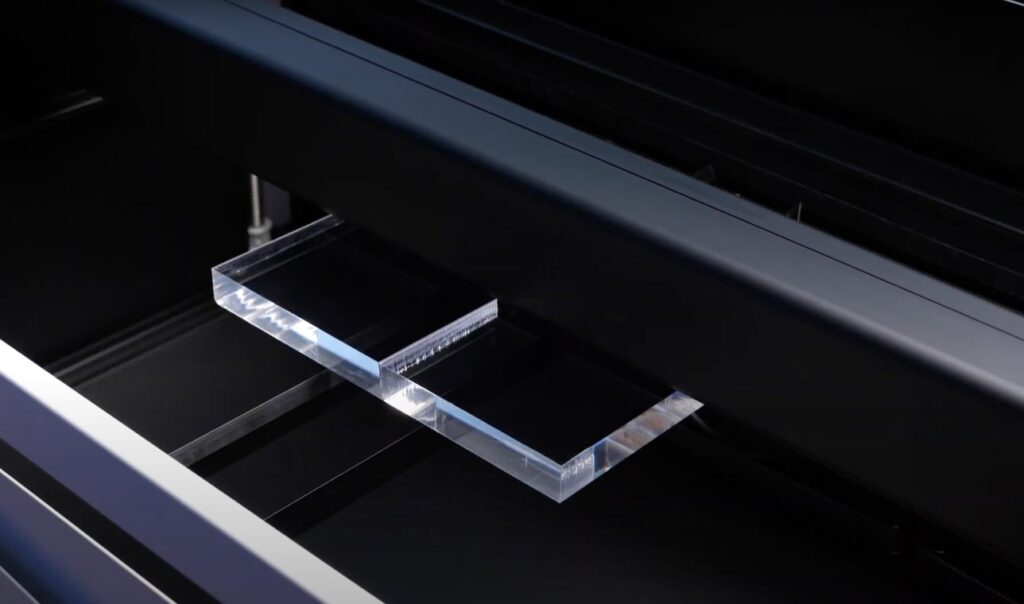

With up to 90W of power, the LX30 is the most powerful machine in its class, effortlessly cutting through materials up to 1″ thick with precision and ease. This unparalleled strength allows for deeper and faster cuts in a greater variety of materials, from hardwoods to thick acrylics, and beyond.

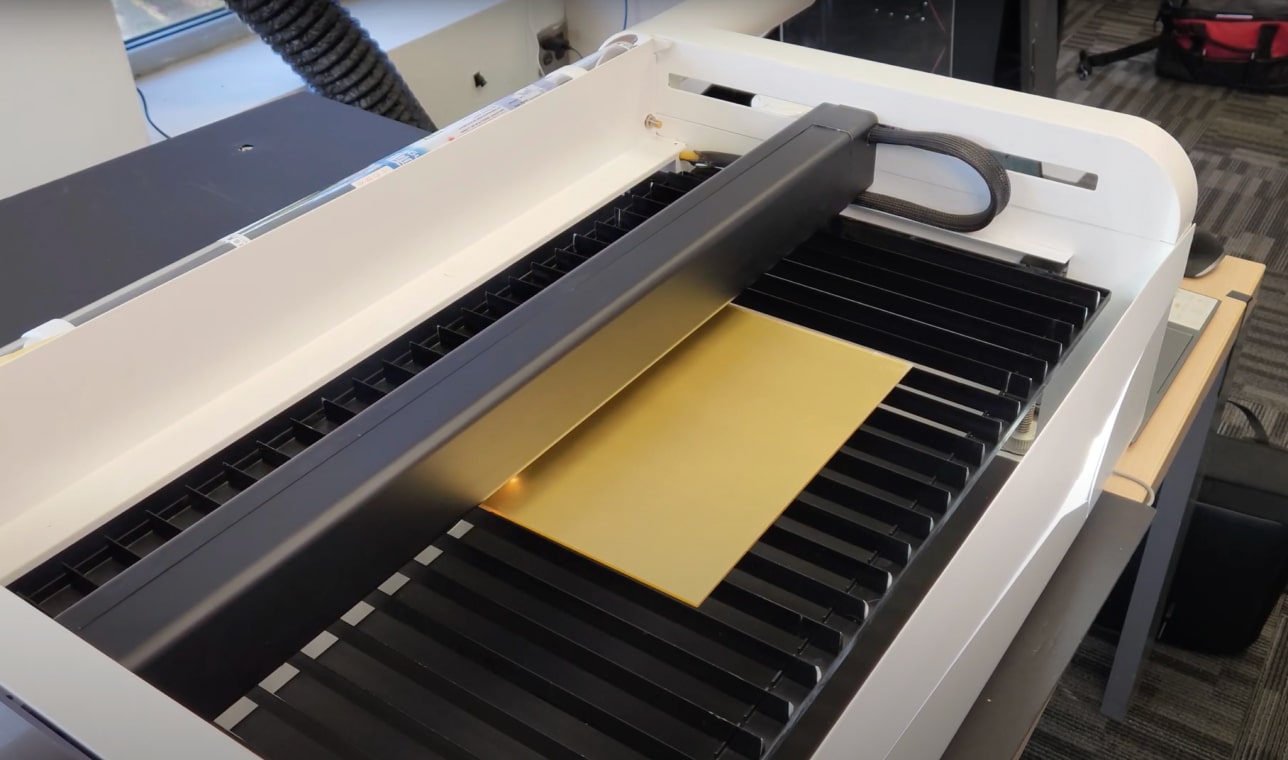

The innovative automatic material feeder is a breakthrough feature that allows you to work with over-sized materials beyond the machine’s standard dimensions. By seamlessly feeding materials through the built-in rollers, the LX30 ensures smooth, continuous production of larger projects without interruption, making it perfect for creating banners, long signs, and other expansive designs.

Material Passthrough Slot

Expand Your Capabilities with Oversized Materials

Autofocus

Always in Focus

Our dynamic autofocus function automatically adjusts the distance from the material with great precision, even on curved surfaces. Now, creators can expect flawless results from the best desktop laser engraving machine ever built.

Our dynamic autofocus function automatically adjusts the distance from the material with great precision, even on curved surfaces. Ensuring flawless results.

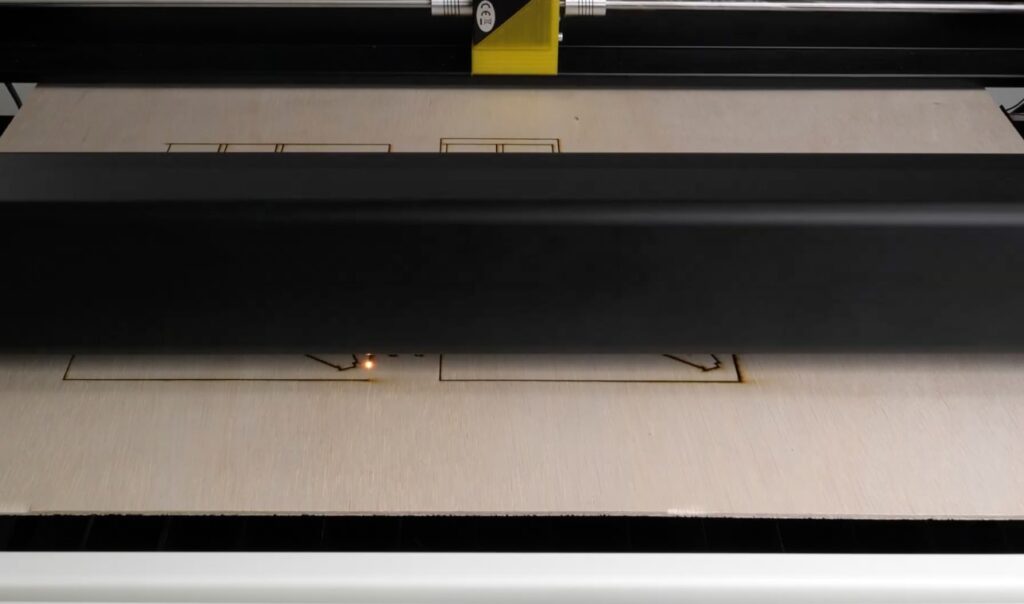

Achieve unparalleled performance with the LX30, delivering remarkable speeds of up to 2000mm/s and pinpoint accuracy with 0.01mm precision. The built-in camera technology not only ensures advanced auto-focus for flawless results but also enables intuitive drag-and-drop designing directly onto your material, streamlining your workflow like never before.

Speed + Accuracy + Autofocus

Fast and precise

Find Your Perfect LX30

The best fit for you between our two LX30 laser cutter and engraver machines depends on your material thickness and engraving demands.

The Elite model’s enhanced power and extra protrusion allow cutting up to one-inch-thick materials in a single pass, making it ideal for deep, dramatic wood engravings and robust projects like signage and layered artwork.

The Pro is better suited for lighter applications. Both machines share the same safety rating, so the choice depends on the scale and intensity of your creative tasks.

- work area 30” x 16” unlimited length with passthrough760 x 410mm unlimited length with passthrough

- dimensions 35.6” x 23.3” x 13.7”900 x 590 x 350mm

- max material height 8"200mm

- power 65W65W

- max speed mm/s 20002000

- 3d printing head

- cnc head

- safety class 11

- dynamic auto focus

- lightburn license

Starting at $195/mo or 0% APR with

- work area 30” x 16” unlimited length with passthrough760 x 410mm unlimited length with passthrough

- dimensions 35.6” x 23.3” x 13.7” with an 8” protrusion900 x 590 x 350mm with an 200mm protrusion

- max material height 8"200mm

- power 90W90W

- max speed mm/s 20002000

- 3d printing head

- cnc head

- safety class 11

- dynamic auto focus

- lightburn license

Starting at $195/mo or 0% APR with

Features

Creative Flexibility

Both models combine a laser cutter, desktop CNC router, and 3D printer for a formidable range of creative projects, with the bonus of serious cost savings.

Unmatched Working Area

Compact and Convenient

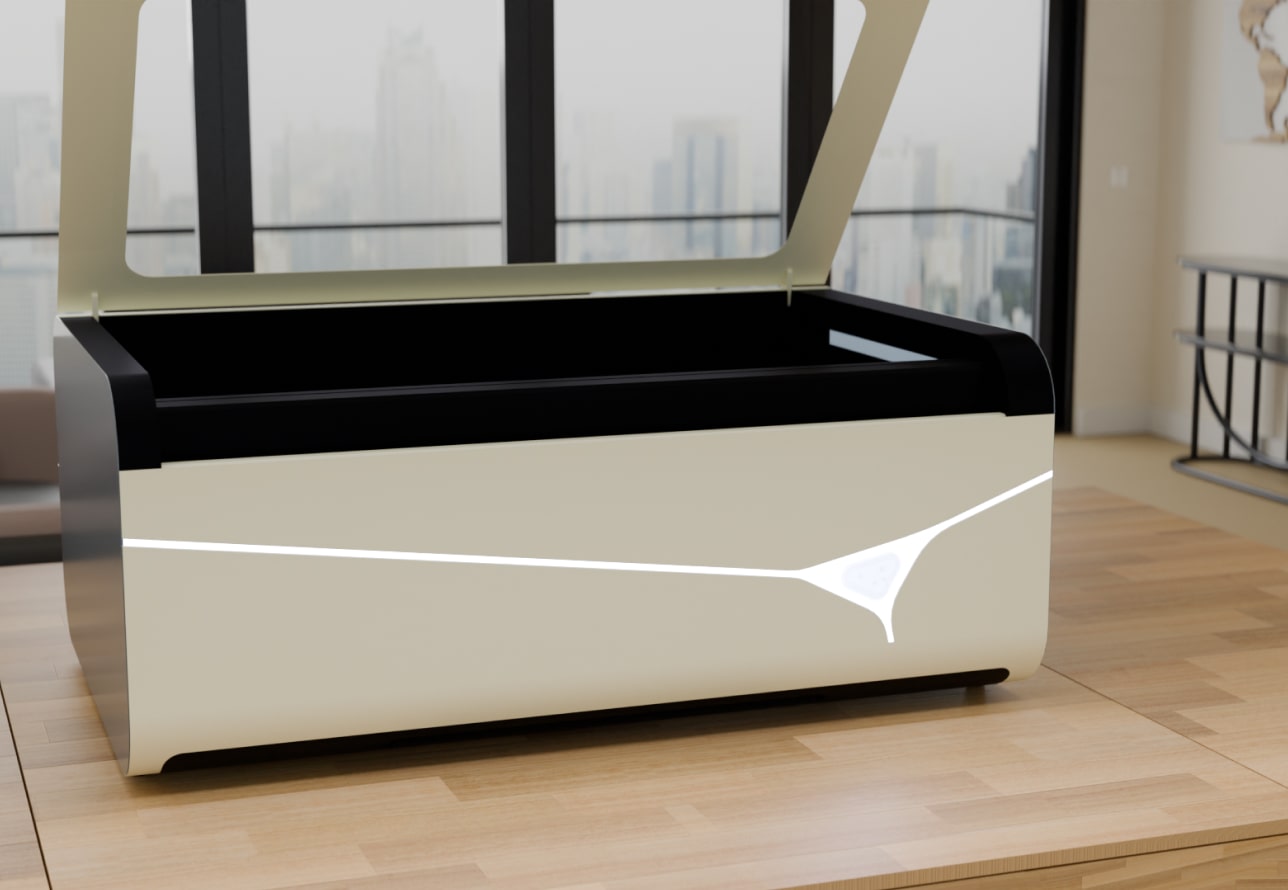

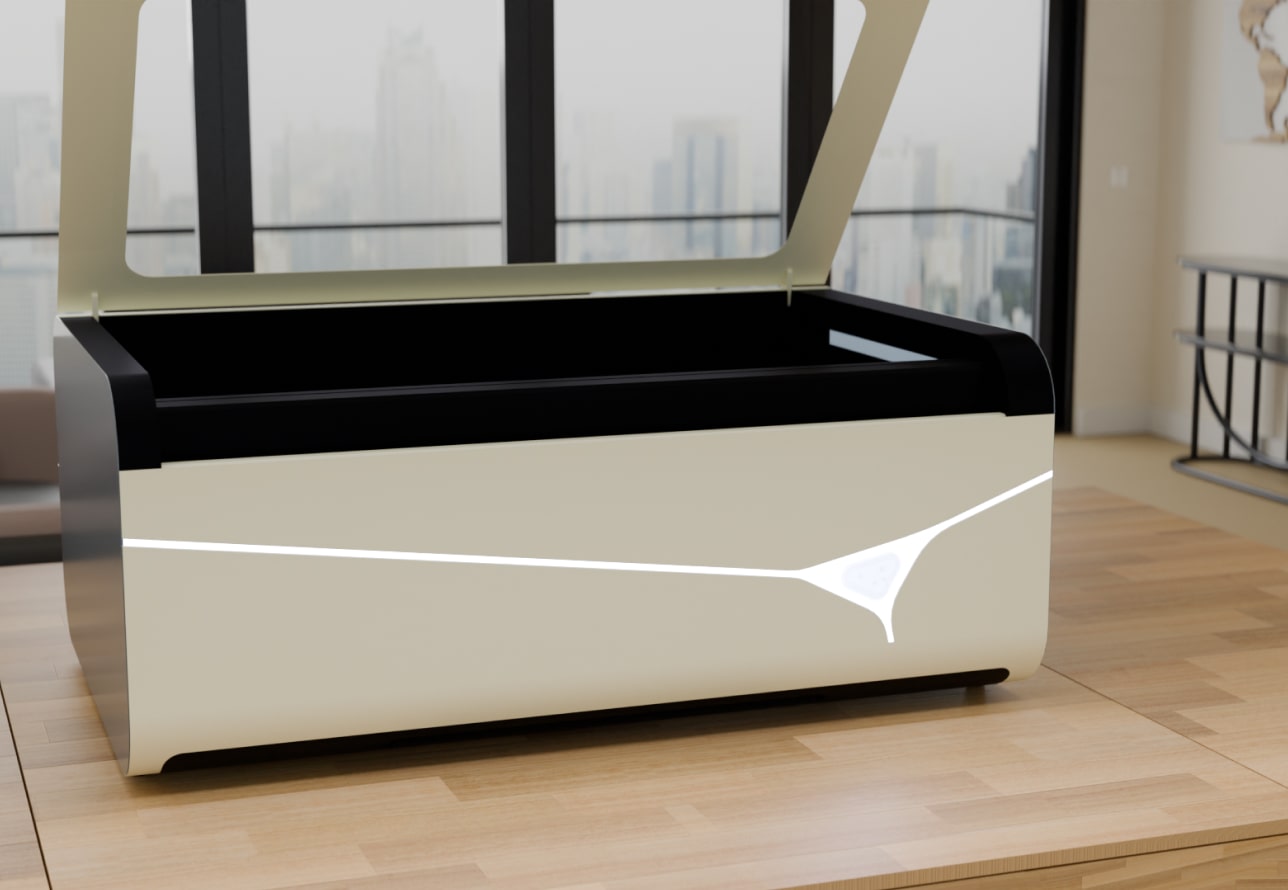

Design

The LX30 is more than just a machine—it’s a statement. With its sleek, modern design and precision-crafted construction, it blends seamlessly into any workspace, studio, or maker space. Designed for both form and function, this cutting-edge laser cutter and engraver machine’s clean lines, premium materials, and intuitive interface make it as stunning as it is powerful. Whether in a home workshop or a professional setting, the LX30 commands attention and elevates any creative or production space.

What Can You Make?

Engrave all the materials above plus: Glass, stone, marble, ceramic, mirror, metals (with laser ink).

FAQs

How does the LX30 integrate multiple fabrication methods into one system?

Our desktop unit merges a CO₂ laser cutter engraver machine, a CNC router, and a 3D printer. Its single chassis eliminates the need for separate machines. With the quick-release mounting design, you can switch heads in minutes. Consolidating multiple functions streamlines workflows and maximizes workspace efficiency.

What software controls are available for design and operation?

Each 3-in-1 3D printer with laser engraving & CNC carving ships with LightBurn. It is a widely used program offering live camera overlay, drag-and-drop alignment, and full control over speed and power settings. Compatibility with standard vector and raster formats ensures your existing files import seamlessly. Real-time preview helps catch errors before firing the laser.

Are safety precautions built into the LX30’s design?

Class 1 enclosure keeps laser emissions fully contained. Subsequently, no special goggles or barriers are required during operation. An emergency-stop button and door-interlocks halt activity instantly if a panel is opened mid-job. This makes the unit classroom and studio-friendly without extra safety training.

How does the autofocus feature maintain perfect focal distance?

Our dynamic autofocus system measures material height and automatically adjusts the laser head. It locates the optimal position, even on curved or uneven surfaces. This removes the need for manual calibration between jobs. Consistent focal alignment delivers uniform engraving depths and sharp cuts.

Can oversized or long sheets be processed continuously?

Yes. Standard passthrough ports and an optional roller-fed automatic feeder enable uninterrupted handling of materials longer than the bed. CO₂ laser machines are perfect for banners, signage, and multi-part runs without manual reloading. Drop-in rollers keep alignment stable throughout long-format jobs.

Which fumes require extraction when cutting various materials?

Organic stocks like wood, acrylic, and leather release smoke and volatile organic compounds. PVC and vinyl materials are also a problem. Fume extraction increases safety by eliminating odors and toxic gases. Keep filters and ducts clear. Capturing harmful particulates ensures operator health and optimal cleanliness.

How do I determine ideal cutting parameters for a new material?

Start with manufacturer-recommended settings for speed and power, then test on scrap samples, adjusting increments to avoid overburn. Note each combination’s result and store presets for repeat jobs. This trial-and-error method yields clean edges without excessive charring.

What maintenance costs should I plan for year one?

With the LX30 laser cutter engraver machine, expect consumables like lens cleaning supplies, air-assist filters, and occasional lens replacement if scratching occurs. In addition, purchasing light lubrication oil and spare belts is necessary for uninterrupted workflows. Minimal downtime ensures annual expenses remain small compared to machine utility.

Solutions for Creators

For Sellers

For Educators

For Businesses

For Hobbyists

Testimonials

4.8

Based on 120 feedbacks

5.0

5.0

a message

5.0

One Stop Steelstock Ltd is an independent steel stockholder and processor that offers a comprehensive range of steel sections, tailored to your specific requirements. With a genuine commitment to understanding our customers’ needs, we aim to provide a cost effective approach to steel purchasing without compromising on quality or service.

5.0

Experts in the design and production of facades and mechanisms, we have been shaping the raw material since 1976.

A dynamic between form, function and finish is at the heart of our know-how, offering a fair and controlled design.

5.0

One Stop Steelstock Ltd is an independent steel stockholder and processor that offers a comprehensive range of steel sections, tailored to your specific requirements. With a genuine commitment to understanding our customers’ needs, we aim to provide a cost effective approach to steel purchasing without compromising on quality or service.

5.0

Experts in the design and production of facades and mechanisms, we have been shaping the raw material since 1976.

A dynamic between form, function and finish is at the heart of our know-how, offering a fair and controlled design.

Ready for Unmatched Creative Freedom?

Contact us today to discover how our laser cutter and engraver machine can meet your needs. Our expert support team is ready to provide all the insights you need to make a confident and informed investment.